ABY™ has 6 manufacturing facilities - 3 are based in Indonesia, 1 in Thailand, 1 in Germany and 1 in Slovakia, producing annually 170,000 MT with more than half a million spindles.

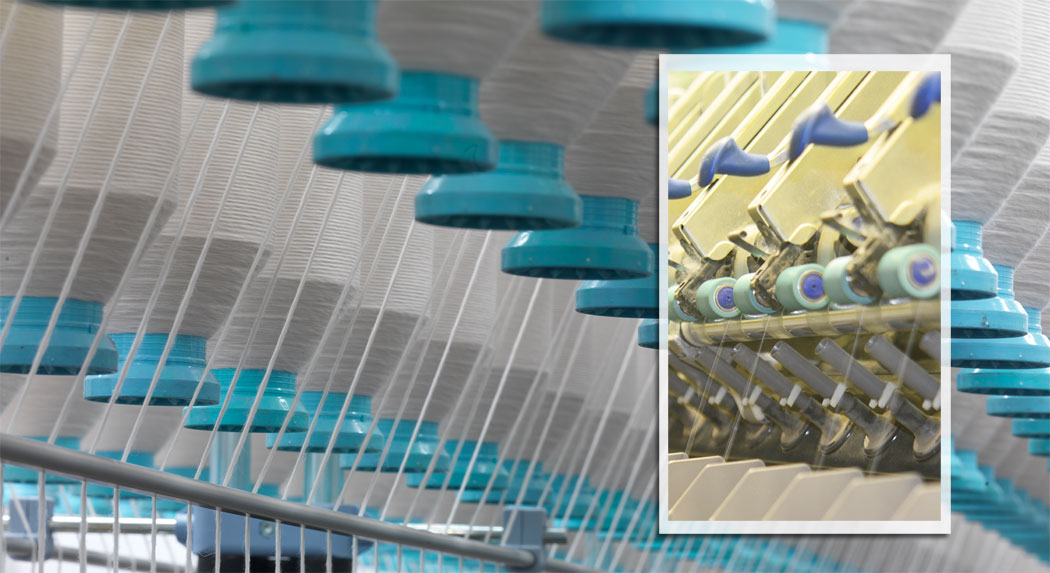

Equipped with highest levels of automation, integrated online process control systems and committed to customer service excellence.

The manufacturing facilities of ABY™ are equipped with textile machineries from best in class suppliers globally and follow stringent quality control procedures to give you yarn which is globally benchmarkable. ABY™ uses machinery from Trutzschler, Schlafhorst from Germany; Howa, Toyota, Murata and Muratec from Japan; Reiter from Switzerland and Savio from Italy to name a few.

PT. Elegant Textile Industry

PT. Elegant Textiles marked the Group’s foray into Indonesia in 1973. PTE currently having a production capacity of 158,880 spindles in addition to the latest Vortex spinning technology with 960 MVS Positions, is the world’s largest producer of rayon spun yarn, contributes to 10% of the global rayon spun yarn trade. PTE is the largest exporter of rayon and rayon-polyester spun yarn with a market share of 20-30% from Indonesia. About 70-80% of its products are exported to customers in the US, Turkey, Korea, Japan, Italy, Greece, Spain, Brazil, Argentina and other locations in Europe and the Asia Pacific region. Nearly half of PT. Elegant’s production caters to niche segments, such as high-quality fabrics for medical applications, car seat covers, upholstery and fancy yarn production among other uses.

The management system of PT Elegant Textile Industry is ISO 45001:2018 certified, the quality management system is ISO 9001:2015 certified and the environmental management system is 14001:2015 certified. It is also certified with Oeko Tex® 100 and ISO 50001:2018 certifications.

PT. Indo Liberty Textiles

PT Indo Liberty is among one of ABG’s yarn manufacturing plant located in Karawang, Indonesia. Established in 1995 with 21,120 Spindles, the facility is equipped with 161,856 Spindles and 4,440 Open End Rotors. We serve the needs of our clients around the world and supply the best quality of customized yarn by engaging in continuous innovation and improvement in manufacturing plant. The company has been accredited for integrated management systems related to quality, environment, health and safety by attaining certifications of ISO 9001:2015, ISO 14001:2015 and ISO 45001:2018 along with Oeko Tex® 100 & ISO 50001 : 2018.

PT. Sunrise Bumi Textiles

PT Sunrise Bumi is among one of ABG’s yarn manufacturing plant located in Bekasi, Indonesia. Established in the year 1979, we have increased the capacity from 17,280 spindles to 90,816 spindles and 2,800 open-end rotors. Engaged in continuous innovation and improvements across manufacturing plants for supplying best in class, quality and customized yarn, we serve the needs of our clients around the world. We are catering to ABY™'s three major segments, namely, fashion and apparel accommodating 65-70% share of total capacity, home textiles 15-20% share of total capacity and technical textiles 10-20% share of total capacity.

The management system of PT Sunrise is certified an Occupational Health and Safety Management System ISO 45001 : 2018, the quality management system is certified ISO 9001 : 2015 and the environmental management system is certified ISO 14001 : 2015. PT Sunrise Bumi Textile is also certified with Oeko Tex® 100 and The Energy management system is certified ISO 50001 : 2018.

Indo Thai Synthetics Co. Ltd

The first overseas venture of the Group, Indo Thai Synthetics commenced operations in 1969 with a capacity of 12,768 spindles. Today, it is Thailand’s leading synthetic yarn spinner and the largest exporter of synthetic yarn from Thailand with a 50 per cent share in the total synthetic spun yarn exports from Thailand. The current capacity has grown to 60,768 Ring Spindles and 3,840 Open End Spinning positions.

Indo Thai Synthetics has been certified meeting the requirements of IS0 9001 : 2015, ISO 14001 : 2015, ISO 45001 : 2018 and ISO 50001:2018 certified. Oeko Tex® has certified raw white and dope dyed fiber quality from Indo Thai Synthetics to be in accordance with Oeko Tex® Standard 100.

Spinnerei Lampertsmühle GmbH

Location – Germany. Incorporated in 1854 with capacity – 50,000 spindles and 150 years experience in the spinning industry, two decades of experience in producing TechTex VAPs. Technical textile yarn manufacture in EU by rev, with superior German quality. Largest partner (by volume) for DuPont for aramids in Europe. Gold partner of Trevira for Trevira CS fibre. Leading brands include Aramex-Garne GmbH for Aramid yarns and Dunova for Sportech. Partnerships with 15+ reputed technical fibre manufacturers.

Spilatex, s.r.o.

Location - Slovakia. Incorporated in 2005, 100% partnership with the German company Spinnerei Lampertsmühle GmbH. Together with the parent plant Spilatex, s.r.o. has a capacity of more than 60,000 spindles with specialties in special grey (white), coloured, or highlighted yarn for the textile manufacture of fabrics.

ABY™ Spindle Installation Capacity Snapshot

PT. Elegant Textile Industry

Established in

1973

Current Capacity

158,880 Ring spindles & 960 MVS Positions

PT. Indo Liberty Textiles

Established in

1995

Current Capacity

161,856 Ring spindles, 4440 OE Positions

PT. Sunrise Bumi Textiles

Established in

1979

Current Capacity

90,816 Ring spindles & 2800 OE Positions

Indo Thai Synthetics Co. Ltd

Established in

1969

Current Capacity

60,768 Ring spindles & 3840 OE Positions

Spinnerei Lampertsmühle GmbH

Established in

1854

Current Capacity

30,000 Ring spindles

Spilatex, s.r.o.

Established in

2005

Current Capacity

31,000 Ring spindles